Creating Industrial Durable Casings for Commercial Electronics

Job Information

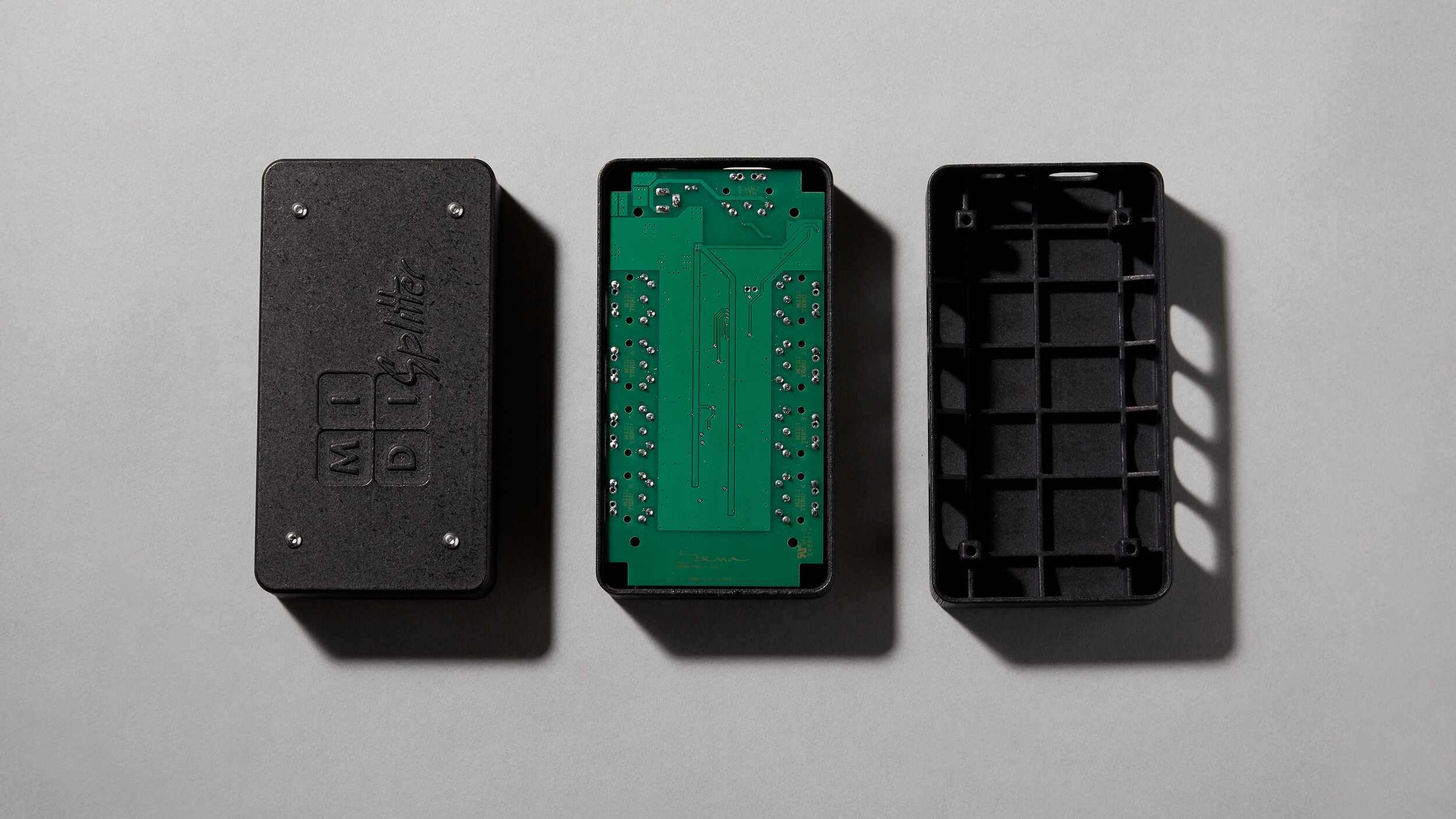

| Midi Thru Case | Batch Production |

|---|---|

| Technology | Selective Laser Sintering (SLS) |

| Material | PA12 Nylon |

| Finish | Vibro-Polishing & Black Dye |

| Part Size(s) | 151 x 81 x 29 mm |

| Quantity | 10 |

| Unit Cost | £34.32 / product |

Customer Info / Context

Tindie is a market-leading resource for electronics DIY projects. Their products are affordable electronics that can be used within a variety of industries. Tindie describes itself as the Hardware platform for the 21st Century. 3D People designed this case as part of a new brand for professional audio electronics casings.

Issue / Challenge

Tindie’s products are usually PCB boards for DIY projects and therefore do not come as a final consumer electronic product with casing. Starting with just the PCB itself, we reverse-engineered the board and designed a case for a perfect fit. The enclosure had to be rugged enough for bands to take on tour and be thrown about during stage installation and de-installation.

Solution

Our case includes a grid structure to increase the rigidity of the final product. The PA12 Nylon material is exceptionally durable and can withstand breaking when dropped. Internal components hold the precious electronics in place and stop the PCB from moving during use. By 3D printing with powder bed technology (SLS), we can produce an economical solution for this end-use product.

Click here to read our materials guide to find out more about the materials we use to print at 3D People UK.

Explore our gallery to see more examples of our previous work.