OUR MANUFACTURING SERVICES

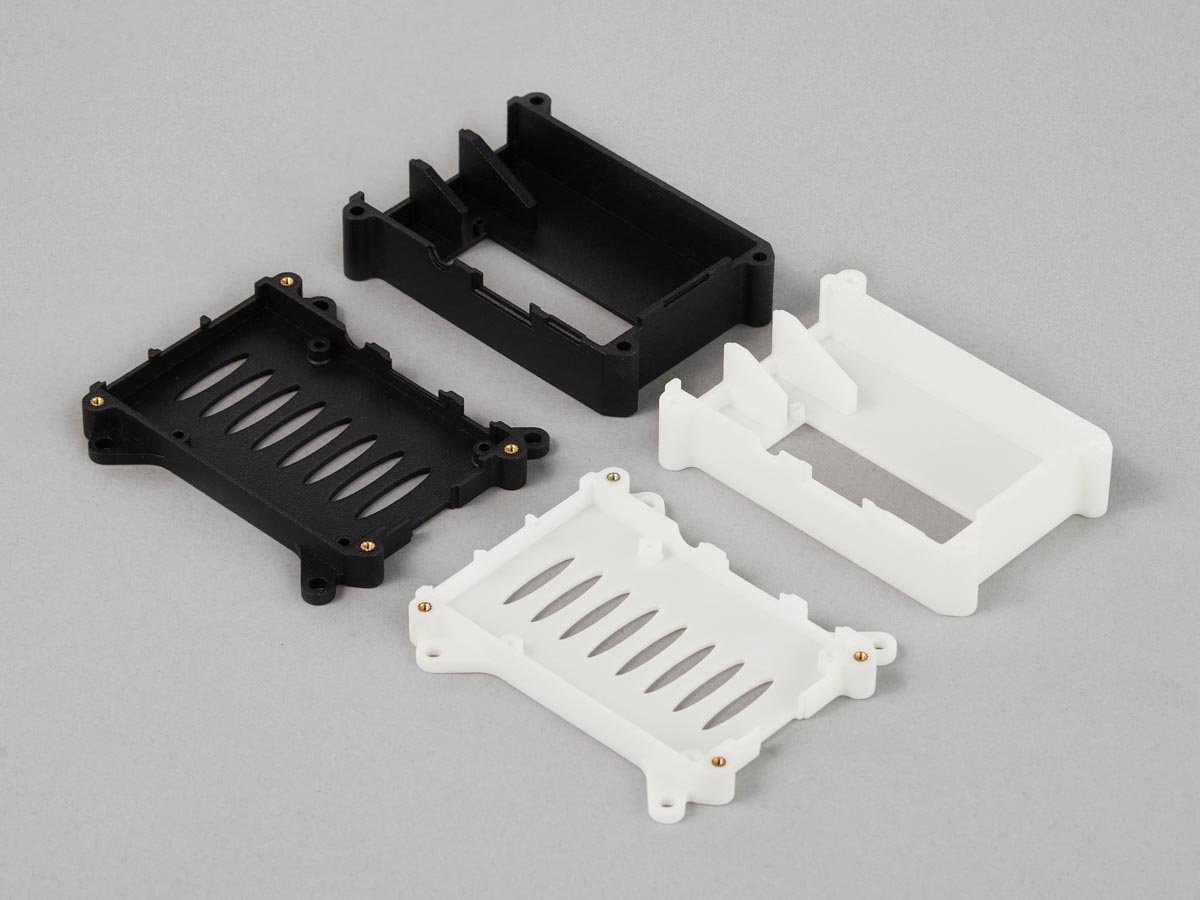

Leverage advanced Multi Jet Fusion (MJF) and Selective Laser Sintering (SLS) technologies to achieve outstanding results for your projects. Unlike other 3D printing methods, MJF and SLS provide unparalleled accuracy, detail, and strength without sacrificing quality. These technologies utilise powder ben fusion processes that ensure surface uniformity and superior mechanical properties, overcoming traditional limitations.