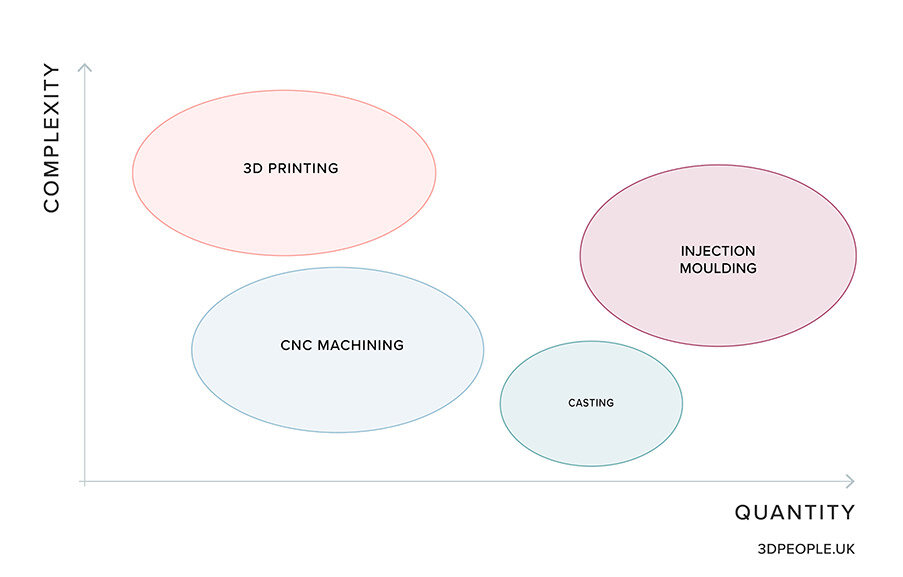

There are many different manufacturing processes available to produce plastic components and it’s not always easy to decide which one to use for your product. This article will compare three different techniques that are often contenders for similar product applications.

Injection Moulding (formative)

3D Printing (additive)

CNC Machining (subtractive)

These processes offer both opportunities and restrictions for your design. If you consider the manufacturing process during the design stage, it will help you to leverage the strengths and mitigate the limitations.

Here we will compare 3D printing to other plastic manufacturing methods in a side by side analysis.

How to compare manufacturing processes

The following factors should be taken into consideration when choosing a manufacturing process.

Volume / Budget How many parts do you need? Each manufacturing process has a relationship between quantity and cost. The number of pieces you need to make can determine which method is economically superior.

Lead time When do you need your parts? Each process requires time for design verification; machine set up, manufacture and post-processes. How long you've got can determine which method is most suitable.

Materials / Finishes What material properties do you need? Polymers are a versatile material group with thousands of material options; however, not all are available for each manufacturing process.

Design constraints What is the geometry of your design? "Design for manufacture requirements" are the constraints that dictate which forms are possible to produce. Each process has different design constraints.

Process flexibility Is your design _final or final_final? Making alterations to your design after the manufacturing process has begun can be problematic depending on the process.

Technology Introductions

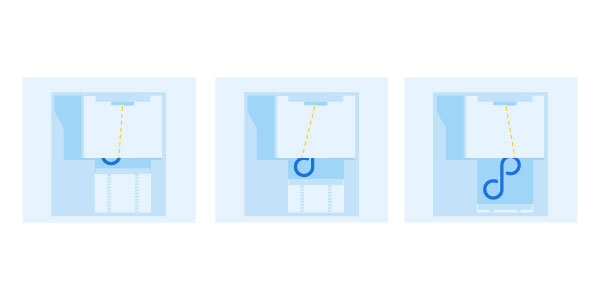

3D PRINTING / ADDITIVE MANUFACTURING

3D Printing is an additive manufacturing process that builds parts by fusing layers of plastic on top of each other. There are many different types of 3D printing technologies available; however, in this article, we will focus only on Fused Deposition Modeling (FDM) and Selective Laser Sintering (SLS) / MultiJet Fusion (MJF).

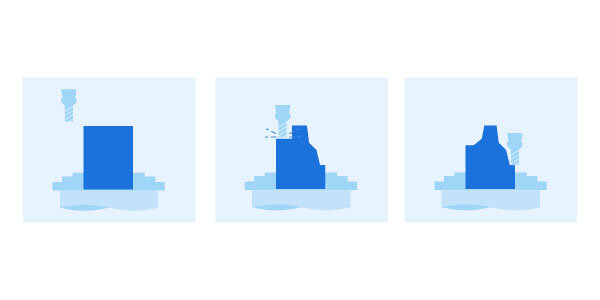

CNC MACHINING

CNC machining is a subtractive manufacturing process that carves parts from a solid block of material. Similarly to 3D Printing, there are many types of CNC machining. In this article, we focus on CNC milling and CNC lathing.

INJECTION MOULDING

Injection moulding is a formative manufacturing process that creates parts by injecting molten plastic into a cavity mould (tool). The types of injection moulding we focus on in this article are rapid & production tooling for single, multi-cavity and family moulds.

Technology Comparison Overview

The main attributes to watch for your product are shown in this table with comparisons between the three manufacturing techniques.

| Attributes | 3D Printing | CNC Machining | Injection Moulding |

|---|---|---|---|

| Start-up Cost | No Cost | No Cost | Tooling Cost £3,000+ |

| Volume* | Low to Medium Volume 1 to 10,000 |

Low Volume 1 to 500 |

High volume 3,000+ |

| Lead Time** | Short 1 - 7 days |

Medium 7 - 14 days |

Long 15 - 60 days |

| Material Selection | 5+ Plastics |

20+ Plastics, Woods, Metals |

100+ Plastics |

| Surface Finish | As Printed shows layer lines, Vibro Polish smooths surface | As Machined shows tool marks, Smoothed, Bead Blasted | Numerous finishes available including glossy, textured & matte |

| Design Constraints | Few | Some - Complexity greatly adds to cost | Many - Design For Manufacture Required |

| Flexible Process*** | Yes | Yes | No |

Learn about 3D printing materials

* Number of units viable for a typical production run

** Lead times based on express service production

***Does this manufacturing process enable easy and consequence free design changes?

SECTION 1. Volume / Budget

The total cost of manufacturing consists of two main expenses:

Start-up cost to begin the process

Unit cost for the price per part.

Injection Moulding

A high start-up cost is required to create the tooling (mould) used to make the parts. A simple tool usually costs more than £3,000 but can be considerably more depending on the complexity, material and finish required.

An exceptionally low unit cost is achievable using IM as the parts are incredibly efficient to produce. The raw material cost is the highest contributing cost to the price per unit.

A high volume of parts must be produced for injection moulding to be economically viable. The savings made on each unit must add up to more than the initial investment. Some tooling costs run into six digits but are used to create very high quantities of parts.

Tool replacements are required after the mould reaches the maximum number of parts it can produce. Tools made from more hardened metals such as steel have a higher yield. These require a more substantial initial investment as they are much more difficult to machine than softer alternatives such as aluminium.

3D printing & CNC machining usually have little to no start-up costs per part but tend to have a small minimum order cost.

CNC Machining

A small start-up cost is required to cover the time spent setting up the machine, part fixturing and generating tool paths from 3D files in a process called CAD to CAM. The start-up cost is known as non-recurring engineering (NRE) cost as it is a one-time fee.

Machining time is an essential factor in the cost of CNC machining. The time it takes to produce one unit is known as the cycle time. The longer the cycle time, the more expensive the part.

The raw material cost of the solid block used to machine parts is another essential contributing cost. More hardened materials are difficult to machine, which increases the machining time.

Complex geometries increase the unit cost for machined parts. To achieve certain forms the part may need to be reset into a new position, increasing the production cost of each unit.

3D Printing

3D Printing has no start-up cost as there is no need for tooling and automated programming of tool paths.

There is a low minimum order cost to cover the setup, processing and logistics of a 3D printing order. Minimum order costs typically range from £30 to £60.

Printing time plays an essential role in the unit costs for 3D Printing. However, there are different pricing structures for each additive manufacturing technology. You can check out the prices for various 3D printing technologies by uploading a 3D file to our instant quote tool.

The material cost is another crucial factor; however, the amount of material required to 3D print an object is not equivalent to the volume of the part. See our pricing page for more information about how we calculate costs for our 3D printing service.

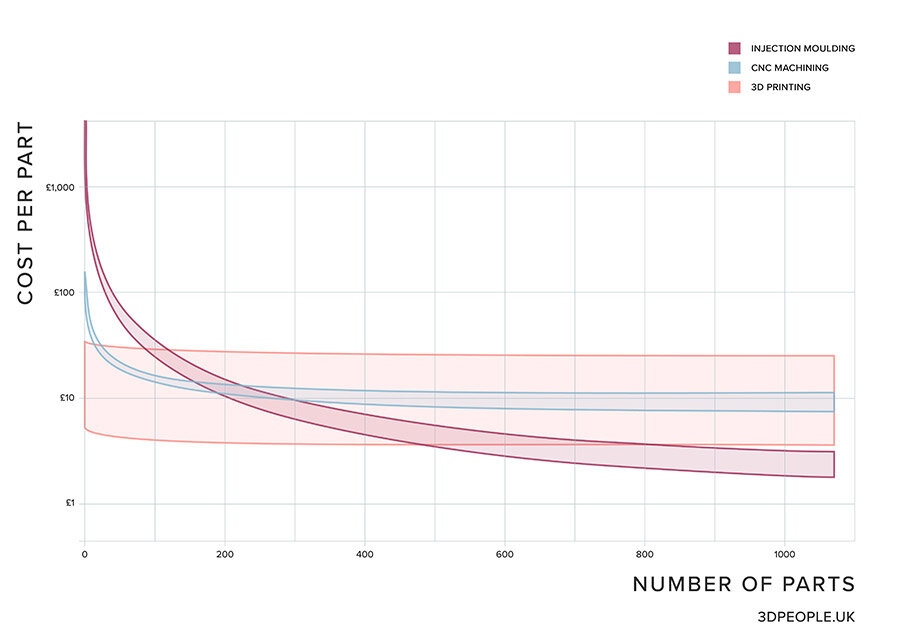

There is a relationship between the unit cost and the volume of units produced for all three technologies. Generally, the more you order, the better your price per item is going to be, regardless of the manufacturing process. However, every manufacturing process has a different type of price/quantity relationship.

Cost by volume for an Example Part

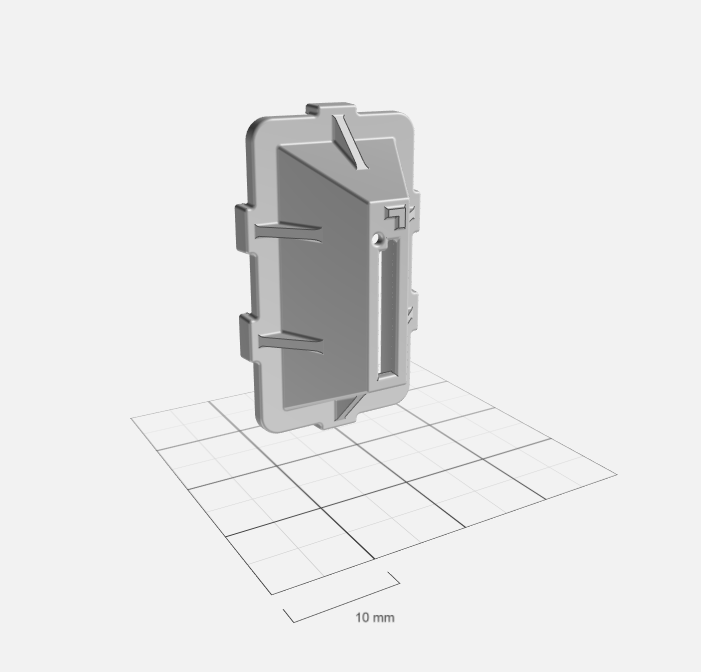

Our sample item is an electronic enclosure (75.0 × 38.0 × 58.0 mm), and as you can see in the table below, the part is ideal for 3D printed production. This price is only possible by using a technique called 3D nesting.

| Process | Material | Tooling Cost | Quantity | Unit Cost | Total* |

|---|---|---|---|---|---|

| Injection Moulding | Nylon | £5,429.27 | 1 500 5000 |

N/A £0.92 £0.38 |

N/A £5,889 £7,329 |

| CNC Machining | Nylon | N/A | 1 500 5000 |

£125.20 £8.06 RFQ |

£125.20 £4,030 RFQ |

| SLS 3D Printing | Nylon | N/A | 1 500 5000 |

£15.59 £2.64 £2.35 |

£15.59 £1,320 £11,750 |

| FDM 3D Printing | PLA | N/A | 1 500 5000 |

£7.02 £0.65 £0.6 |

£7.02 £325 £3,000 |

| CFF 3D Printing | Carbon-filled Nylon | N/A | 1 500 5000 |

£17.99 £2.22 £2.04 |

£17.99 £1,110 £10,200 |

*Prices represent an average from popular European manufacturers.

This graph displays the relationship between unit cost and volume for all three technologies. The data gathered is from a wide range of parts with various sizes and complexities.

Multiple Parts

Does your product need to be made from multiple components? This question is essential to consider because it will influence your decision-making process. If your product consists of many parts and you are looking to produce it with injection moulding, you are going to need numerous moulds or a family tool. The additional tooling requires an increased start-up cost. In comparison, 3D printing and CNC machining have no tooling costs, so it's more affordable to produce more parts.

SECTION 2. Manufacturing Lead Times

Lead time When do you need your parts? Each process requires time for design-verification, machine set up, manufacture and post-process. How long you've got can determine which method is most suitable. In general, these are the lead times for the three manufacturing processes:

3D Printing - 2-7 business days

CNC Machining - 10-25 business days

Injection Moulding - 20-30 business days

Different companies often have different lead times, so you always want to confirm before developing any specific expectations about when you are going to get your first product. Factors outside of your control, such as their current workload, operational capacities, and staffing, will affect the lead time you are going to get.

3D Printing is the fastest way to begin producing products, enabling you to get your first item in a matter of days.

SECTION 3. Materials & Finishes

For functional parts where a lot of strength and durability is required, the material selection will be of utmost importance. Finishes are also essential for the usability and appeal of your product. There are not many finishes available beyond sanding or smoothing products, but there are other ways to create a finish by including textures in the design of the part.

3D Printing has access to a medium range of plastic materials and finishes. These include thermoplastics and some composite materials. The surface finish of most 3D printed parts shows layer lines from the printing process. Depending on the 3D printing technology used, a variety of finishes are available to smooth the surfaces. E.g. Vibro-Polishing

CNC Machining supports a decent number of plastic, wood and metal materials. With CNC you can get your product with an "as machined" or smoothed finish, together with any designed patterns.

Injection Moulding can utilise over 100 different materials, including thermoplastics and silicone rubbers. IM parts can come with a variety of finishing options such as bead blasting, etching, and matte finishes. Also, dual shot injection moulds create products with two materials in the same cycle, such as plastics toothbrushes with a silicone grip.

SECTION 4. Design Constraints

How complex is your part geometry? Design-for-manufacture requirements are the constraints that dictate which forms are possible to produce. Each process has widely different design constraints.

These constraints include minimum thickness, draft angles, undercuts and many more. Please see our design rules for 3D Printing to help design for our service.

SECTION 5. Manufacturing Process Flexibility

As designers, we understand that a product can always be improved.

Even though it's likely that you've designed, iterated and prototyped, sometimes specific features of the product get overlooked. Occasionally changes need to be made during the manufacturing process.

3D Printing is the most flexible technology between the three. It's incredibly easy (and comparatively cheaper) to stop production of one design, edit and update the production run. If you are still developing, most often than not you print multiple iterations simultaneously, especially when using SLS 3D Printing.

CNC machining is similarly flexible in its ability to absorb design changes without significant financial consequences. However, changes need more time and require some additional cost.

Making changes with Injection Moulding is extremely difficult in comparison to the other two manufacturing methods. To facilitate a significant design alteration, you may need to remake the tooling from scratch. There is a small window of time during the mould making process where you can run some test units and make minor changes to the tool before it gets hardened.

Once you are happy with your design, the mould gets hardened, and further changes become incredibly slow and expensive.

At 3D People, we often use SLS 3D Printing to manufacture the initial release of a product. 3D printing alpha product runs enable our customers to take their product to market, test the waters, and improve their design before volume IM manufacture.

Conclusion

Choosing the right manufacturing process is crucial to your product's success. Depending on a multitude of factors, the "correct" technology will change accordingly.

| Attributes | Pros | Cons |

|---|---|---|

| 3D Printing | Capable of creating complex geometries No start-up cost Instant orders Design flexibility Fast order completion |

Large objects are expensive Limited finishes Low volume discounts |

| CNC Machining |

No start-up cost Immaculate finishes Metals available |

Volume insensitive Expensive per item cost Low volume discounts |

| Injection Moulding |

Durable products Lots of finishes Full colour choice Wide material choice Dual shot Low price per item |

Lines and ejector marks High start-up cost Long lead times |

For the early period of a product's lifecycle, 3D Printing is often the superior manufacturing method. It's easy, affordable, and fast to start creating high-quality products. Once you are confident your product can reach an economy of scale, you will have the option to transition to mass manufacturing methods like injection moulding.

A design optimised for 3D Printing may use complex geometries, therefore transitioning to injection moulding may be impossible for some designs.

CNC Machining is more expensive and slower than 3D Printing, and the material selection is similar. CNC creates products out of solid blocks of material, ensuring density and water tightness.

Injection moulding has the most extensive plastic material selection but requires more time and investment to start the production process. Once started, IM produces units fast, but the design is challenging to adjust.

Just like any tool in a workshop, there is no ultimate best-tool. Each has a superior use case, and in the end, it's up to you to decide which manufacturing technology is best for your product.