In almost every product, component or assembly, the cost is a significant element driving decisions from idea conception right the way through to steady-state manufacturing. An engineer or designer can evaluate the cost to manufacture something against its benefits to the product or service.

3D printing, like many other manufacturing methods, has different drivers of manufacturing costs related to the equipment and the parts you are looking to manufacture. If engineers can understand the differences between the technologies and the underlying drivers of part cost, they stand to make considerable savings for their projects.

This article explores the manufacturing costs of MJF and SLS technologies. We explain the drivers of manufacturing costs per unit for each technology and provide several pricing scenarios for different parts types to visualise which technology might be cheaper for your specific application. We also discuss some tried and tested methods that you might be able to apply to get your price per part down even further.

So, MJF or SLS, Which is Cheaper?

Long story short, it depends on the geometry of your part. In most instances, smaller parts are usually more economical with SLS, whereas larger, more sparse parts are cheaper with MJF. If you have 3D files ready for quoting, you can upload them to our Instant Quote tool to check the prices online. The Instant Quote tool uses two pricing methods for SLS, Boundary Box and Low-Density Pricing. For MJF, we use a single pricing method called Material Pricing. The tool processes your 3D files to simulate the true manufacturing costs to make you the most competitive price.

Drivers Of Manufacturing Cost Per Part

Part Volume

The volume of your part directly relates to the amount of material required to produce it and, therefore, the cost. The larger the part, the more material needed, and consequently, the higher the price. The material pricing applies to both MJF and SLS technologies, although the material costs differ significantly due to the use of agents in the MJF process.

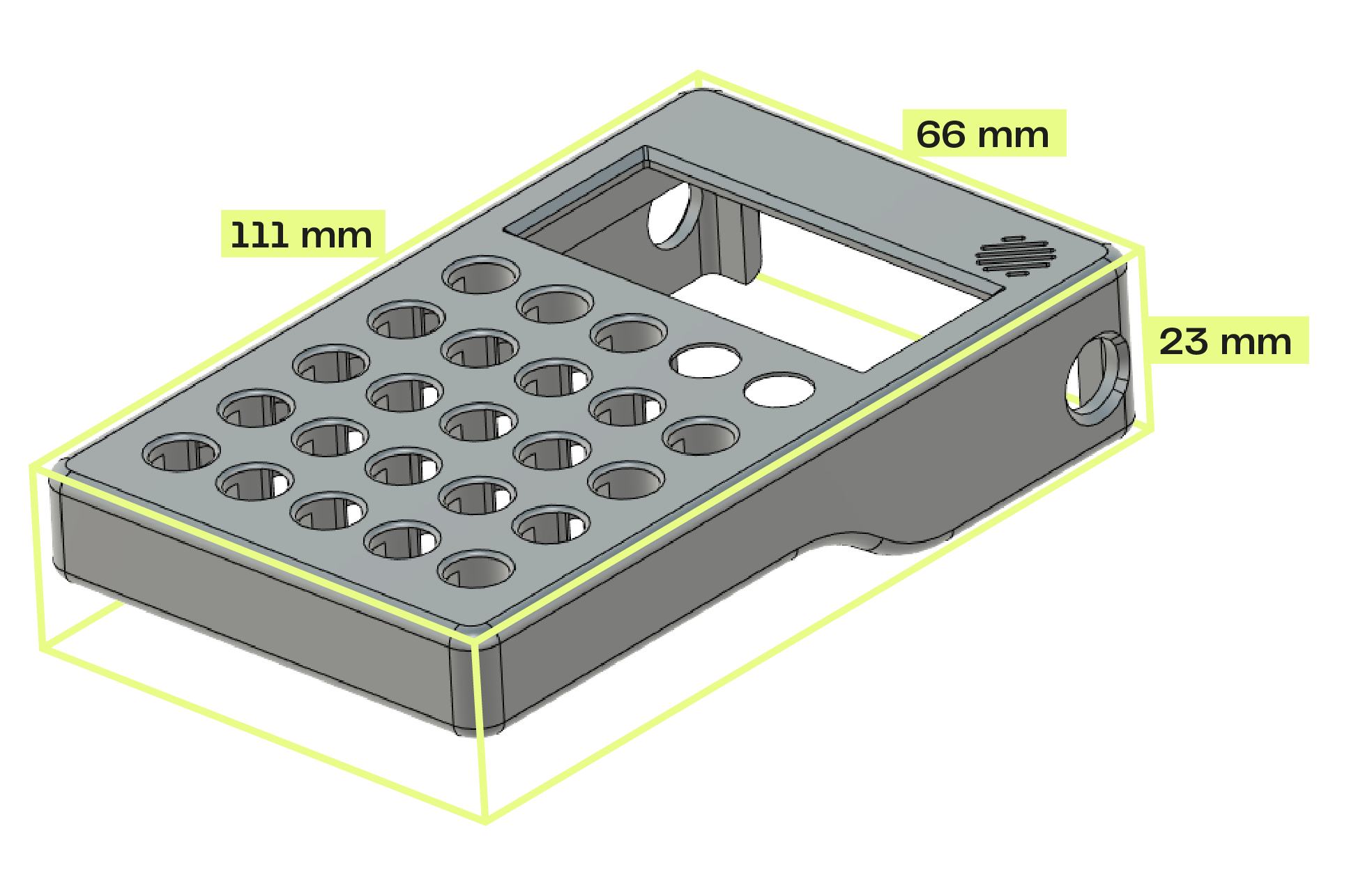

For both technologies, a byproduct of the printing process is that a small amount of material is left unusable around your part. The unfused powder close to the surfaces of the parts becomes degraded by the high temperatures of the printing process. Therefore, we calculate the offset volume of your part to account for this waste material, highlighted in the illustration below.

Part bounding Box

The bounding box of your part is the part length x width x height. The bounding box can be large for some geometries, even if the part itself has a small volume of material. The example electronics case below highlights this. The bounding box can affect the manufacturing costs of your part when manufacturing with SLS, which uses XYZ bounding Box Pricing or Offset pricing. You can read more about this here.

Consumables Costs

Both MJF & SLS use powder PA12 Nylon for their printing processes. They differ because SLS doesn’t require any other consumables, whereas MJF uses fusing and detailing agents. The fusing and detailing agents are expensive, and the amount used per part is proportional to the part volume. The significantly higher costs of the agents to the PA12 Powder means that part volume significantly affects the price.

Recycle Rate

The MJF and SLS 3D printing process recycles unsintered powder leftover from previous builds. The high temperatures inside the build chambers degrade the powder and necessitate mixing with fresh, virgin powder to optimise part quality. The SLS process uses 50% recycled PA12 and 50% fresh PA12 Nylon powder. MJF can achieve a higher recycling rate of up to 80% recycled powder.

The recycling rate is significant in affecting the manufacturing cost of different geometries. A low density, sparsely packed build generates lots of used powder. The higher recycling rate of MJF technology means that virtually all unfused powder can easily be recycled and reused. Therefore, with MJF technology, it is cost-effective to produce larger, low-density parts. SLS technology is limited to 50% recycled powder making it impossible to recycle all of the unsintered material generated in low density builds. Therefore, SLS technology requires a higher packing density to avoid the disposal of used powder. Smaller, nestable and high-density parts make denser builds and are more economical to manufacture with SLS technology.

Our Pricing

We aim to be as transparent as possible regarding our pricing structure for our different technologies and materials. Depending on the geometry of your parts and the manufacturing technology, the various cost drivers become more or less significant.

On our Pricing Information page, you can read more about the specific pricing methods we use for MJF, SLS and FDM and why we use them.

Can I Make My Part Cost Less?

At 3D People, we want to offer you affordable, best-in-industry prices for our industrial 3D printing technologies. There are several methods you can apply to your parts to reduce the overall printing costs for both SLS & MJF, which we briefly discuss below.

Nesting for cheaper SLS parts

The use of nested parts is an excellent way to reduce the cost of SLS 3D printing. A nest has several parts positioned so that their XYZ bounding boxes overlap, reducing the overall bounding box size from what it would be if they were separate. These parts are then saved into one file to generate a price based on the smaller bounding box. Combining geometries into a single file can result in multiple 3D prints for the price of one.

Nesting parts in MJF is not cost-effective due to the offset pricing method used.

We have explored in detail the best method for nesting parts in SLS and what to consider when nesting in this post.

Hollowing and Lattices for cheaper MJF parts

There are a variety of software applications that can allow you to quickly hollow out solid models when preparing them for 3D printing. The guiding principle behind this is that using less material will result in a cheaper manufacturing cost due to the reduced volume of a hollowed part. When hollowing your parts, it’s crucial to incorporate a powder drainage hole into your model. Otherwise, you won’t have access the cost savings using this method.

Alternatively, you can design a lattice structure, as shown in the following image. Both hollowing and lattices allow you to reduce the part material and weight while maintaining nearly all of the part structural integrity.

Hollowing and incorporating lattices is not cost-effective with SLS technology due to the bounding box pricing method.

Volume price breaks for cheaper MJF and SLS parts

At 3D People, we want to support you in your small, medium and large batch manufacturing endeavours. A great way to reduce overall part cost is to manufacture a larger quantity of the same file.

We can offer competitive price breaks for large volume orders in MJF and SLS. We can offer up to 35% off your order price through competitive discounts.

| Quantity | Discount |

|---|---|

| 1 unit | 0% |

| 2 + units | 5% |

| 10 + units | 10% |

| 50 + units | 15% |

| 100 + units | 20% |

| 250 + units | 30% |

| 1000 + units | 35% |

You can read more about our quantity price breaks here.

Pricing Scenarios

We’ve highlighted some examples of different types of parts and their manufacturing costs in SLS and MJF technology. You might see a similar part to yours that you can use to guide your choice of technology. These examples show how the geometry of your part might influence the overall manufacturing costs in our two powder bed fusion technologies.

Exchanger Housing

This part is cheapest when produced with SLS technology.

The part is relatively compact and dense, meaning that it fills up the majority of its XYZ bounding box. Therefore, the recycling rate within MJF becomes less significant in the part price and makes this technology more expensive.

43.2 x 26.1 x 70.0 (mm)

SLS PRICE

£10.03

MJF PRICE

£13.64

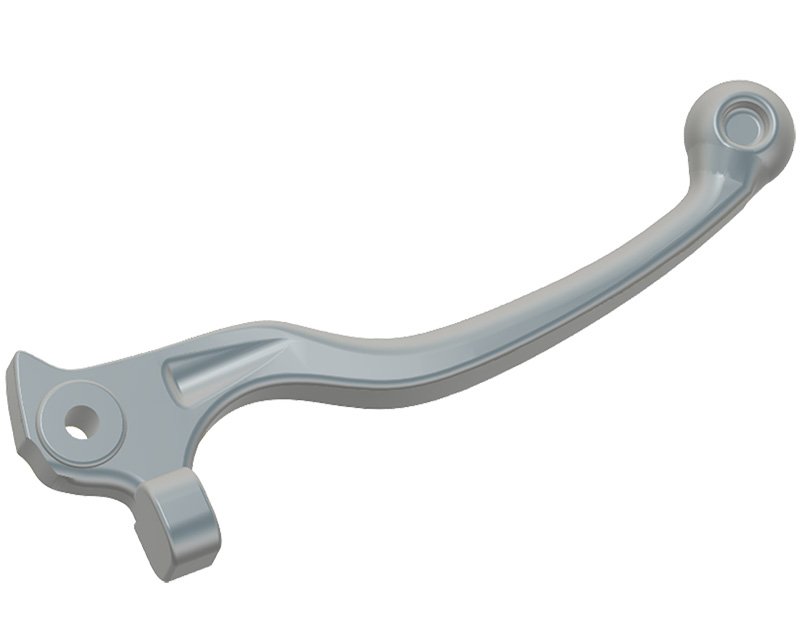

Bike Brake Lever

This bike lever is significantly cheaper when produced using MJF.

This part has a large bounding box in relation to its volume.

The recycling rate is much higher in MJF, meaning sparse parts with a large bounding box are more economical to produce.

43.4 x 139.3 x 20.0 (mm)

SLS PRICE

£14.41

MJF PRICE

£7.66

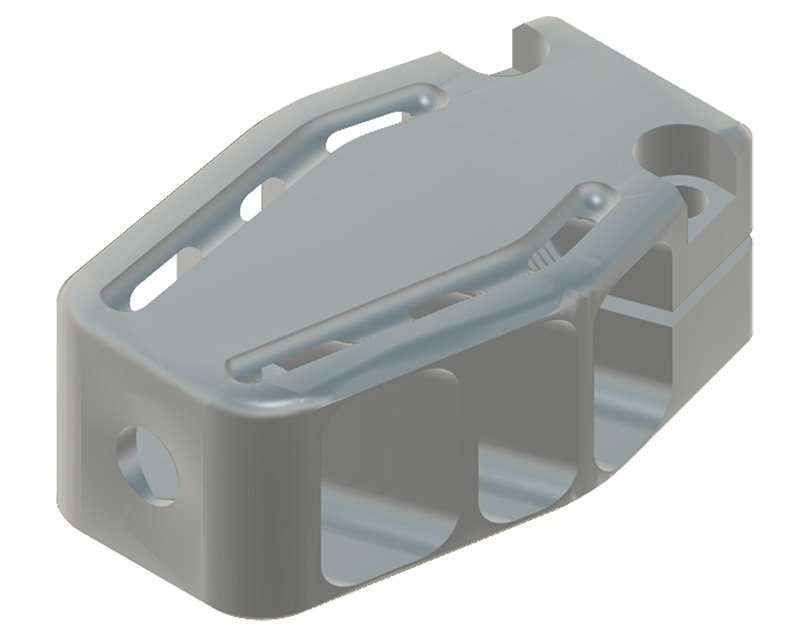

Bracket

This bracket is of a similar price in SLS and MJF technology.

The part isn’t compact or solid and isn’t particularly sparse either, which means the two pricing methods result in a similar part price.

52.0 x 52.0 x 30.0 (mm)

SLS PRICE

£10.24

MJF PRICE

£10.84

Handwheel

This part has a large amount of space in its bounding box relative to its volume, resulting in some considerable savings on this part if manufactured from MJF technology.

80.0 x 80.0 x 40.0 (mm)

SLS PRICE

£30.62

MJF PRICE

£18.52

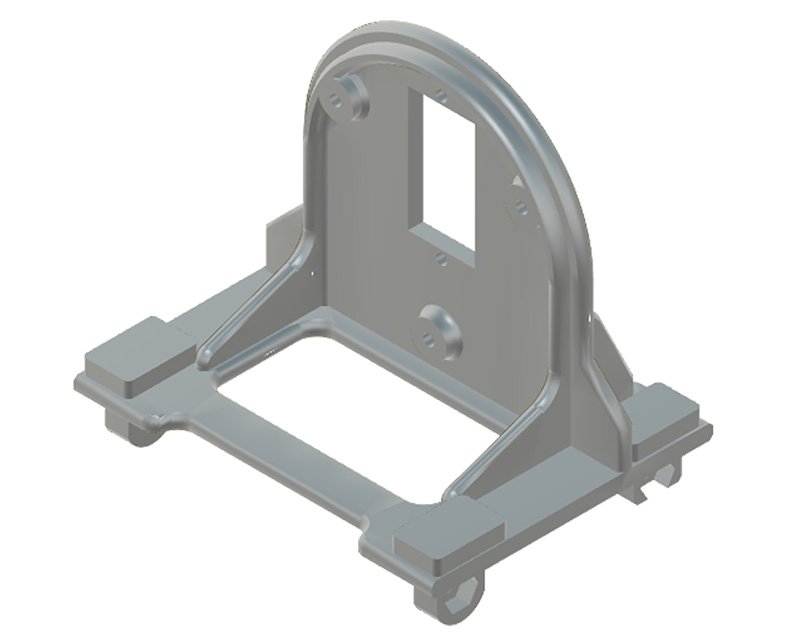

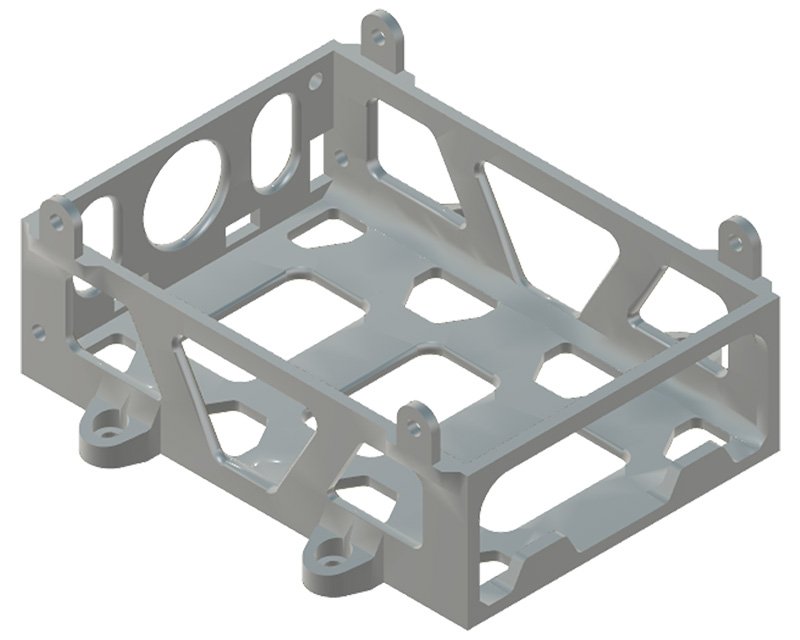

Camera Bracket

This bracket has a large amount of space within its bounding box.

MJF is the cheapest technology for this component.

56.0 x 70.0 x 67.0 (mm)

SLS PRICE

£29.47

MJF PRICE

£13.16

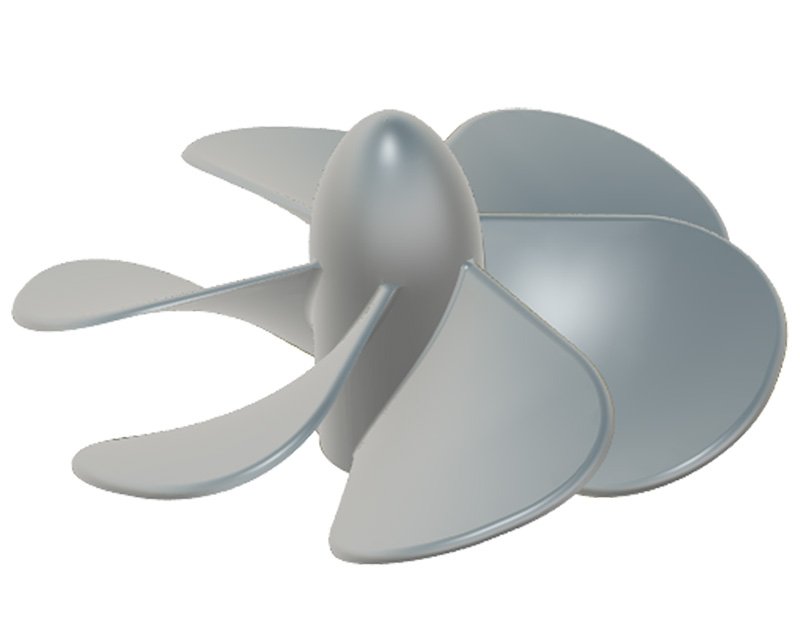

Aero Prop

This aero prop is the most extreme example of price differences between the two technologies.

MJF is the cheapest for this part.

86.6 x 99.0 x 7.4 (mm)

SLS PRICE

£9.18

MJF PRICE

£2.75

Enclosure

This bracket has a large amount of space within its bounding box.

MJF is the cheapest technology for this component. This part is nested in a later pricing scenario that drastically alters the part cost to make SLS more economical.

100.0 x 90.0 x 39.3 (mm)

SLS PRICE

£42.57

MJF PRICE

£26.78

Knurled Bolt

This part is small and reasonably compact, where the volume of the part fills at least half of the part bounding box.

The low material price of boundary box pricing lends itself to small, dense parts.

SLS is the cheaper technology for this part.

20.0 x 20.0 x 36.0 (mm)

SLS PRICE

£2.03

MJF PRICE

£3.12

Electronics Casing

This electronics casing is more economical to produce using SLS Technology.

The part is small and compact, leading to more competitive pricing using the XYZ bounding box method.

12.0 x 50.0 x 37.0 (mm)

SLS PRICE

£3.12

MJF PRICE

£5.06

RC Propeller

Another excellent example of a much cheaper MJF part - this RC propeller has a lot of space around the blades where material can be recycled using MJF.

This part is, therefore, more economical to produce using MJF Technology.

59.3 x 63.2 x 31.1 (mm)

SLS PRICE

£14.17

MJF PRICE

£7.69

NEST EXAMPLE

Enclosure, 28x Coupling Nuts

This example of nested parts shows the enclosure, along with 28x coupling nuts at a cost of £1 per unit.

The parts are cheapest in SLS.

In SLS technology, the price is the same for the Enclosure part with or without the 28x coupling nuts. For MJF, the cost has increased with the increased part volume.

100.0 x 90.0 x 39.3 (mm)

SLS PRICE

£42.57

MJF PRICE

£43.09

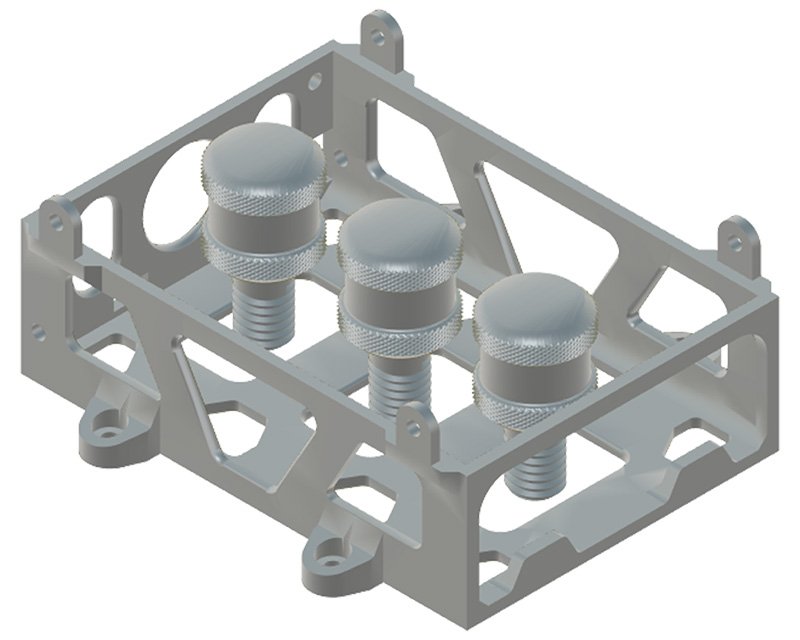

NEST EXAMPLE

Enclosure, 3x Knurled Bolts

This nest example is the same price in SLS as the previous example, even though the parts are different in size and quantity.

SLS technology is the cheapest option for this part.

100.0 x 90.0 x 39.3 (mm)

SLS PRICE

£42.57

MJF PRICE

£46.68

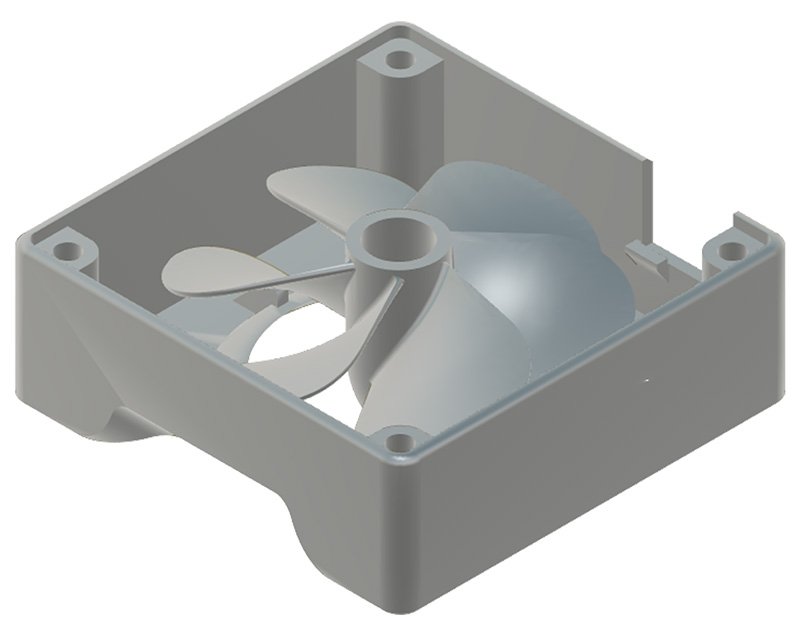

NEST EXAMPLE

Casing, RC Propeller

This part is more economical to manufacture in SLS technology.

These two low-density parts are individually more affordable to produce in MJF but become more economical to manufacture in SLS when nested together.

74.0 x 74.0 x 30.9 (mm)

SLS PRICE

£20.79

MJF PRICE

£26.17

8x Separate Coupling Nuts

This pricing scenario shows 8x coupling nuts grouped in the same .stl file. Due to the small size, they’re priced at the minimum body price of £1.00 per body.

102.0 x 12.7 x 21.6 (mm)

SLS PRICE

£8.00

MJF PRICE

£8.00

SPRUE EXAMPLE

8x Sprued Coupling Nuts

This pricing scenario shows the same 8x coupling nuts as the previous example, however, these parts are joined by sprues.

Sprued parts influence the overall part cost.

This example shows that sprued parts are significantly cheaper to manufacture in SLS. Sprues have minimal effect on cost in MJF.

102.0 x 12.7 x 21.6 (mm)

SLS PRICE

£3.97

MJF PRICE

£7.56

Summary

Additive Manufacture is a fast and cost-effective production method for low, medium and volume production. Both SLS and MJF 3D printing technologies offer significant cost advantages in comparison to traditional manufacturing methods.

On average, the prices for MJF and SLS 3D printing are similar

For sparse & large parts, MJF technology is usually the more economical option

For smaller and more compact parts where the volume fills most of the bounding box, SLS technology is usually the more economical option

For nested or sprued parts, SLS technology is usually the more economical option

We are always here to inform you about using 3D printing within your product or service. Please don’t hesitate to get in touch with questions about the different technologies, materials and finishing methods we offer.