WHY USE VIBRATORY POLISHING?

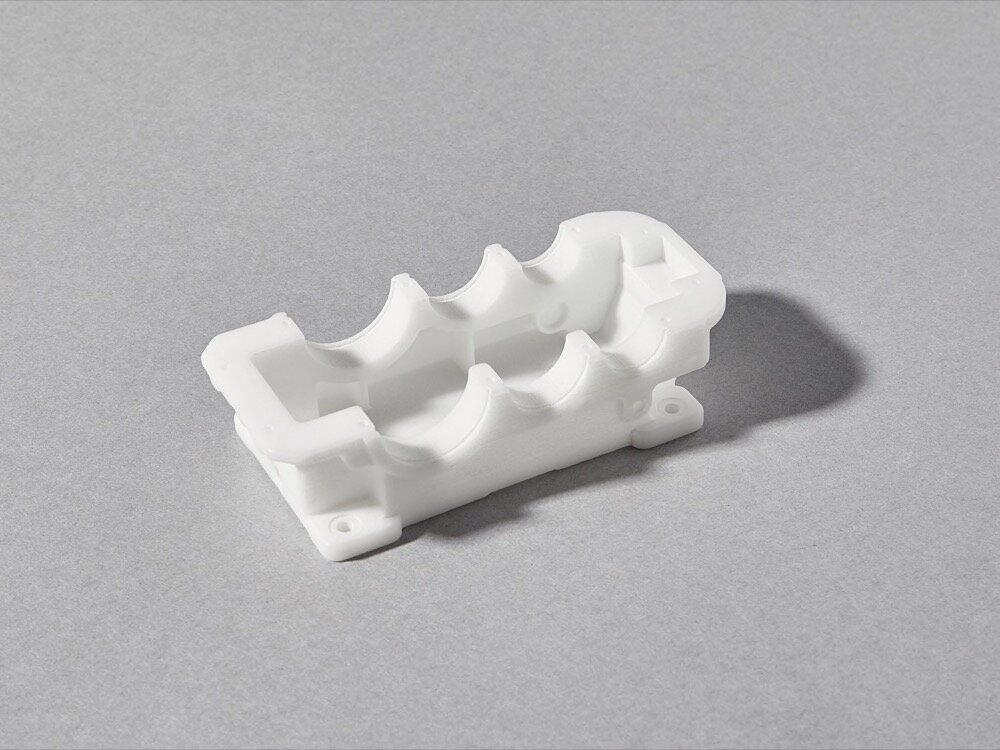

Vibro polishing is ideal for powder bed 3D printed parts that require a smooth surface finish. As printed, SLS and MJF components have a slightly grainy surface. The polished finish is more dirt-resistant and feels closer to an injection moulded part. This makes Vibro polishing attractive for end-use components